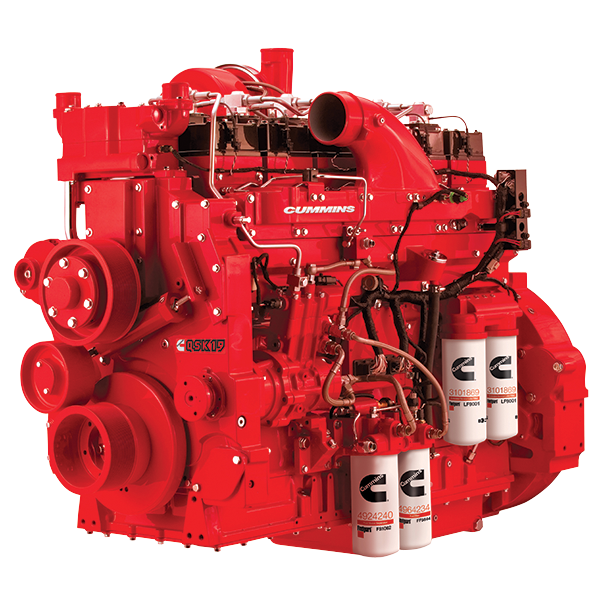

Cummins Mining Engine K19

Power 506-800 hp

377-597 kW

Torque1175-2032 lb-ft

1593-2755 N•m

Tier 2 / Stage II

Overview:

With ratings from 506-800 hp (377-597 kW), the QSK19 delivers the lowest life cycle cost with the longest life-to-overhaul of any engine in its class. In the QSK19, standard features like state-of-the-art electronic controls and a modular common-rail (MCR) fuel injection system ensure clean, efficient performance, minimum maintenance and superior uptime for quarry and underground equipment - in the same compact footprint as its K19 predecessor. Optional features help reduce maintenance downtime and costs even further.

The QSK19 with MCR features help reduce noise emissions and engine vibration, resulting in a safer and more comfortable work environment for equipment operators and mine personnel. Advanced electronic controls enable cold starts down to -5° F (-20° C) without starting aids.

Cummins analysis-led computer modeling has enabled Cummins to optimize the in-cylinder combustion system of the QSK19 which results in achieving U.S. EPA Tier 2 and Tier 3 emissions levels with minimal impact to fuel consumption.

The durability of the base engine is well-proven, with thousands of QSK19 engines in haul trucks, excavators, drills and wheel loaders delivering superior uptime around the world - above ground and below.

Every QSK19 engine is covered by Cummins base warranty, one of the most comprehensive and simplest plans in the industry

· High Pressure Modular Common Rail (MCR) Fuel System - Cummins high pressure fuel pump and modular common rail system provides full-authority electronic control of the fuel pump and injectors for precise control of both injection pressure and timing. Each injector includes its own integrated accumulator, which helps to eliminate pressure pulsation between injectors and improve stability.

· Quantum System Electronics - High-speed Electronic Control Module (ECM) with a self-cooling mount is isolated from detrimental vibration loading. A field-proven, fully-sealed wiring harness with fail-safe connectors integrates the ECM with the engine sensors for optimized engine performance, monitoring and protection. Quantum system technology is ideal for tough mining applications that demand continuous uptime carrying hundreds of tons capacity.

· High-efficiency Turbochargers from Cummins Turbo Technologies - Feature a turbo speed sensor, watercooled bearing housings and better airflow for maximum power and long-life.

· State of the Art Combustion Control System - Features enhanced electronics integrated with upgraded sensors and a powerful new Electronic Control Module (ECM) for peak engine performance at all altitudes and under every load condition.

· Two-Stage Cummins Oil Filters - Combination full-flow and bypass filtration to effectively remove harmful sludge and up to three times as many contaminants to reduce engine wear.

· Ferrous Cast Ductile Iron Piston - Provide increased strength and durability to handle increased cylinder pressures for longer life-to-overhaul.

· Prelub™ System - Distributes oil to rifles and friction surfaces and builds oil pressure before cranking can occur. A pressure switch assures proper oil pressure in the main rifle to reduce the risk of starting the engine without oil in the sump or filters. Prelub is a standard option on all mining engines due to proven success in extending engine life-to-rebuild.

· Piston Cooling Nozzles - Deliver a cooling stream of oil beneath each piston crown and bowl rim for long life with increased reliability.

· Revised Combustion Bowl Geometry - Allows the QSK19 to reach certified emissions levels in-cylinder, eliminating the need for aftertreatment.

· Advanced Engine Monitoring - Allows you to monitor engine performance cylinder by cylinder on a real-time basis. Also provides trending charts to help you keep preventive maintenance to a minimum without risking engine damage.

· Premium Fan Drive – Incorporates large matched and sealed bearings, improved oil seals, and an improved idler system. The fan drives have fixed fan centers with tensioning provided by a manually adjusted and maintenance free idler. The fan drive is available with or without an electronically controlled oil-actuated fan clutch.

· Engine Model | Advertised hp (kW) @ rpm | Peak Torque lb-ft (N•m) @ rpm |

QSK19-800** | 800 (597) @ 2100 | 2275 (3084) @ 1500 |

QSK19-760 | 760 (567) @ 2100 | 2275 (3084) @ 1500 |

QSK19-755 | 755 (563) @ 1800 | 2275 (3084) @ 1400 |

QSK19-700* | 700 (522) @ 2000 | 2200 (2981) @ 1500 |

QSK19-700* | 700 (522) @ 1800 | 2200 (2981) @ 1400 |

QSK19-675* | 675 (503) @ 1800 | 2200 (2981) @ 1400 |

QSK19-560* | 560 (418) @ 2000 | 1775 (2407) @ 1500 |

QSK19-525* | 525 (391) @ 2000 | 1775 (2407) @ 1500 |

QSK19-506* | 506 (377) @ 1800 | 2032 (2755) @ 1300 |