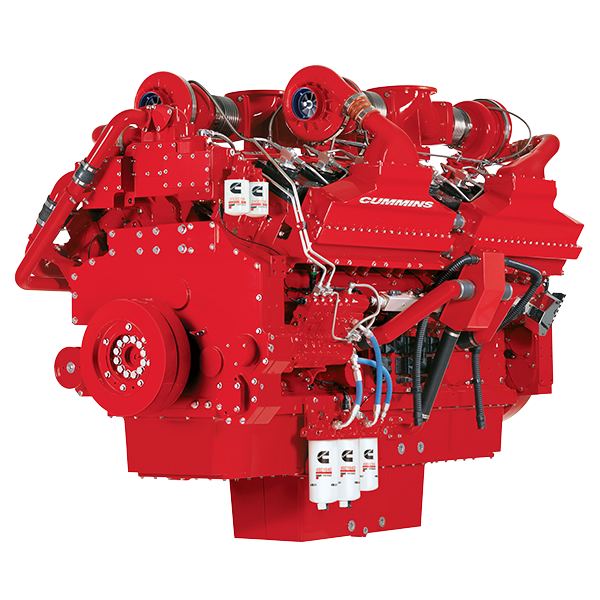

Cummins Mining Engine QSK60

QSK60 FOR MINING (NON-CERTIFIED)

Power 1782-2700 hp

1329-2013 kW

Torque6169-7839 lb-ft

8364-10628 N•m

Overview:

The QSK60 engine was developed for mining and designed based upon the strength, performance and durability of the legendary Cummins K2000E. With thousands of engines installed by nearly every major mining equipment manufacturer, you can be sure to find a QSK60 operating reliably in every corner of the world. This is because these engines have a lower operating cost per ton with better reliability than other mining engines of their size. Whether you're powering a large excavator, loader or haul truck, you can expect exceptional fuel economy for years to come with an absolute minimum of downtime. In fact, QSK60 engines routinely achieve over 95% uptime in mining operations with load factors exceeding 40%. Plus, even Cummins engines with non-certified emissions ratings generate clean power at former EPA Tier 1 levels.

The 16-cylinder QSK60 is available with single-stage turbocharging or a two-stage version for high-altitude and high load-factor applications, and is capable of delivering up to 2700 hp (2013 kW) at 12,000-foot (3,658-meter) elevations without power derate.

Quantum System technology includes Advanced Engine Monitoring that allows you to better monitor equipment performance cylinder by cylinder on a real time basis. It also provides trending chart capability for informed preventive maintenance to maximize operation and reduce downtime.

Every QSK60 engine is covered by Cummins base warranty, one of the most comprehensive and simplest plans in the industry.

· Forged High-Strength Tensile Steel Crankshaft - Along with dual viscous dampers, reduces gear train wear and counterweights provide vibration damping for long engine and equipment life.

· Heavy-Duty Front Gear Train - Low gear loading and high fatigue strength for dependable service.

· Cummins Integrated Electronic Control System - Allows users to tailor fuel system calibrations to most unique application requirements.

· Quantum System Electronics - High-speed Electronic Control Module (ECM) with a self-cooling mount is isolated from detrimental vibration loading. A field-proven, fully-sealed wiring harness with fail-safe connectors integrates the ECM with the engine sensors for optimized engine performance, monitoring and protection. Quantum system technology is ideal for tough mining applications that demand continuous uptime carrying hundreds of tons capacity.

· High-Pressure Injection (HPI) Fuel System - Provides a high-peak injection pressure for optimum combustion for low emissions and better fuel economy. HPI fuel injection provides a “soft” injection start for lower combustion noise. Other benefits include excellent cold-starting characteristics and improved transient response at all engine speeds.

· Power Cylinder Package - One-piece Ferrous Cast Ductile (FCD) iron pistons provide the strength and durability to handle high cylinder pressures for long life. Seven-bolt cylinder head supports increased power output with improved breathing and higher fuel efficiency.

· Dual Piston-Cooling Nozzles - Direct cooling streams of oil beneath each piston for long life with increased reliability.

· Wiring - Embedded in a solid foam material and completely sealed in an aluminum housing for reliability in harsh environments.

· Prelub™ System - Distributes oil to rifles and friction surfaces and builds oil pressure before cranking can occur. A pressure switch assures proper oil pressure in the main rifle to reduce the risk of starting the engine without oil in the sump or filters. Prelub is a standard option on all mining engines due to proven success in extending engine life-to-rebuild.

· Two-Stage Cummins Oil Filters - Also available as Fleetguard® combine full-flow and bypass filtration to effectively remove harmful sludge and up to three times as many contaminants to reduce engine wear.

· Premium Fan Drive – Incorporates large matched and sealed bearings, improved oil seals, and an improved idler system. The fan drives have fixed fan centers with tensioning provided by a manually adjusted and maintenance free idler. The fan drive is available with or without an electronically controlled oil-actuated fan clutch.

Engine Model | Rated Power | Peak Torque | Rating Type |

QSK60 - 2700* | 2700 (2013) @ 1900 | 7839 (10628) @ 1500 | Intermittent |

QSK60 - 2500* | 2500 (1864) @ 1900 | 7260 (9843) @ 1500 | Intermittent |

QSK60 - 2300 | 2300 (1715) @ 1900 | 6677 (9053) @ 1500 | Intermittent |

Q SK60 - 2200** | 2200 (1641) @ 1800 | 7175 (9728) @ 1500 | Continuous |

QSK60 - 2000 | 2000 (1491) @ 1900 | 6169 (8364) @ 1500 | Intermittent |

QSK60 - 2000 | 2000 (1491) @ 1800 | 6169 (8364) @ 1500 | Continuous |

QSK60 - 1875 | 1875 (1398) @ 1900 | 6169 (8364) @ 1500 | Intermittent |

QSK60 - 1875 | 1875 (1398) @ 1800 | 6169 (8364) @ 1500 | Continuous |

QSK60 - 1800 | 1800 (1342) @ 1900 | 6274 (8506) @ 1500 | Intermittent |

QSK60 - 1782 | 1782 (1329) @ 1900 | 6274 (8506) @ 1500 | Intermittent |